Identify Deviations in Pyranometer Measurement for Recalibration When Needed

This case study highlights the successful implementation of an automated solution to compare daily irradiance measured by pyranometers across a portfolio of 60 PV assets in four countries. The solution detects relevant deviations between pyranometers with deviations, and assets with average irradiance deviating from the satellite value. This solution has improved operational efficiency by providing continuous visibility of irradiance measurement devices on site and facilitating calibration when necessary.

CONTEXT

The customer, a company with a portfolio of 60 PV assets in several countries, faced challenges in comparing the irradiance measured by the different pyranometers installed on site, and early detection of measurement problems requiring recalibration.

CHALLENGES

The client faced the following challenges:

- Delayed Manual Processing: Benchmarking at the end of the contract year resulted in a lack of monthly visibility and problems with negotiating availability and contractual PR with the operator.

- Timely recalibration: Detecting problems with irradiance measurement and recalibrating the devices promptly was difficult, and recalibration was not being carried out when really necessary.

- Continuous Visibility: There was no system to provide continuous visibility on the status of the pyranometers and the accuracy of the measurements.

SOLUTION

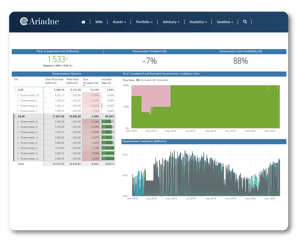

Quintas Analytics developed and implemented a complete automated solution to address the above challenges:

- Daily Comparisons: The system compared daily irradiance readings from each pyranometer at a given asset.

- Deviation Detection: Pyranometers with relevant deviations from the mean were automatically identified.

- Automatic Exclusion: Pyranometers with deviations greater than 5% of the mean were excluded from the overall irradiance calculation.

- Comparison with Satellite Irradiation: The resulting average irradiance was compared with satellite data.

- Daily Notifications: The management team received daily notifications listing deviations of pyranometers and assets with average irradiance deviating from the satellite value.

RESULTS AND BENEFITS

Implementing the solution had a significant impact on operational efficiency and measurement quality:

1. Early Detection: The daily comparison made it possible to detect irradiation measurement problems early.

2. Enhanced Contract Negotiation: The team was able to address measurement issues with the operator in a timely manner, pointing out those periods where pyranometers had been excluded from the average calculation due to deviation.

3. Effective Recalibration: Continuous visibility facilitated the recalibration of pyranometers when necessary.

4. Improved Efficiency: The automated process reduced the need for manual work and annual benchmarking, speeding up the

approval of contractual calculations and the payment of damages for noncompliance where applicable.

CONCLUSIONS

The solution implemented for the comparison of pyranometer measurements in a PV portfolio proved a great success in improving operational efficiency and measurement quality. Process automation, daily comparison and automatic notifications provided essential tools for effective management and process optimisation. This solution sets a valuable example for the management of similar projects in the field of solar energy and the improvement of measurement accuracy.