Detect Discrepancies in Invoice Production to File Claims

This case study presents the successful implementation of an automatic solution to collect and compare the energy production measured by the SCADA with the production invoiced by the offtaker for a portfolio of 250 PV plants in Italy. The solution allowed the automatic detection of discrepancies and notifications of them to the offtaker, improving transparency, billing accuracy and revenue management in the context of PV power generation.

CONTEXT

The client, a leading independent power producer (IPP), managed a large portfolio of 250 photovoltaic plants in Italy. The client supplied power to three different offtakers under contractual agreements that stipulated the volume of power and the agreed tariffs. However, there were challenges in reconciling the actual production measured by the SCADA and the production reported by the offtakers in their invoices, which sometimes led to discrepancies.

CHALLENGES

The client faced the following challenges:

- Discrepancies in Production: Production figures reported by offtakers frequently did not match SCADA measurements, which created uncertainty in the billing and revenue recognition process.

- Manual Reconciliation: Manual comparing and reconciling production figures required much time and effort on the part of the asset management team, increasing the risk of human error, and delays in resolving discrepancies and closing the billing.

- Transparency and Trust: The client sought to improve transparency and trust in relationships with offtakers, by providing a systematic and automated way of notifying discrepancies and initiating the resolution procedure.

SOLUTION

Quintas Analytics designed and implemented a comprehensive solution that addressed the above challenges:

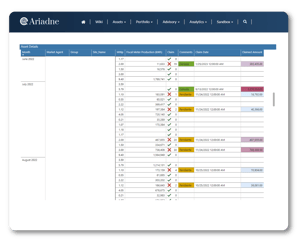

- Data Integration: A system was devised to collect and centralise the SCADA production data and the production data reported by the offtakers through their invoices.

- Automated Comparisons: An automatic comparison algorithm was developed that contrasted SCADA production data with the data billed by the offtakers.

- Discrepancy Detection: The system automatically identified any significant discrepancies between the production figures from both sources and generated alerts.

- Filing of Complaints: The system automatically notified the offtakers of any discrepancies detected.

RESULTS AND BENEFITS

Implementing the solution had a positive impact on production and revenue management:

1. Early Detection: Discrepancies were automatically detected and reported, allowing for faster resolution and avoiding a backlog of problems.

2. Improved Transparency: Automatic notification of discrepancies improved transparency in the relationship with offtakers and strengthened trust.

3. Time Saving: Automation reduced the time required for manual reconciliations, freeing up resources for more strategic tasks.

4. Optimised Revenue: Quick detection and correction of discrepancies ensured that the client received the correct revenue, and on time.

CONCLUSIONS

The implementation of this energy production comparison and discrepancy detection solution proved to be successful in managing a portfolio of 250 PV plants in an environment of multiple offtakers and different contract tariffs. Process automation, data integration and automatic notifications improved accuracy, efficiency and confidence in production and revenue management. This solution lays the foundation for more effective and transparent management in similar solar PV projects.