Calculate the Impact of Australian Network Operators' Instructions to Assess Their Effect on Projects

This case study presents the successful implementation of an automated solution to collect power limitation setpoints sent by the Australian Energy Market Operator (AEMO) and estimate the daily production losses caused by these setpoints in a portfolio of five PV assets in Australia. The solution also calculated the daily availability of the assets, excluding the effect of AEMO setpoints. The implementation of this solution improved the accuracy of the availability assessment, reduced manual effort and mitigated the risk of error in calculations, streamlining the work of the Asset Management team and improving communications for the Asset Management team.

CONTEXT

The client, a leader in the European solar energy industry, had recently entered the Australian market, managing a portfolio of five PV assets with an average capacity of 100 MW. Accurately assessing the availability and production losses caused by AEMO's power limiting setpoints was essential to facilitate communication with plant operators and to quantify the effect of these setpoints.

CHALLENGES

The client faced the following challenges:

- Complex Assessments: Assessing the impact of AEMO power limitation setpoints on availability and estimating production losses was a complex process that had to be carried out manually.

- Data Matching: Matching the daily SCADA production data with the setpoints reported by AEMO required time-consuming effort and increased the risk of errors.

- Data Accuracy: Ensuring the accuracy of availability and production loss calculations was essential to facilitate communication with the on-site operator, to understand the practical effect of the setpoints and make informed decisions.

SOLUTION

Quintas Analytics devised and implemented a complete automated solution to address the challenges mentioned above.

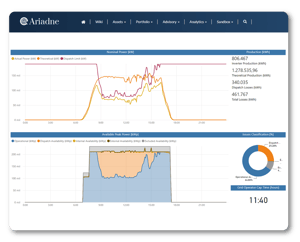

- Data Integration: A system was created to automatically collect the power limitation setpoints sent by AEMO and the production data from the SCADA.

- Calculation of Production Losses: The solution estimated daily production losses caused by the AEMO setpoints, based on the irradiance measured at the plant and the limitation's effect on the power supply.

- Availability Assessment: Algorithms were implemented to calculate the daily technical availability of the assets, excluding the effect of AEMO setpoints, to facilitate communication with the operator and focus on the assets' actual operational problems.

RESULTS AND BENEFITS

Implementing this solution had a positive impact on operational efficiency and accuracy regarding the assessment of availability and production losses caused by AEMO capacity limitation setpoints, as well as with regard to communications with the on-site operator:

1. Workload Reduction: Automation eliminated the daily requirement to manually match SCADA production data and

setpoints.

2. Improved Precision: The automated solution reduced the risk of human error in availability calculations and loss estimation.

3. Up to Date Information: The daily assessment allowed for more timely and accurate decision making, improving communications with the on-site operator.

4. Optimised Operations: A more detailed understanding of production losses improved operational efficiency and planning.

CONCLUSIONS

Implementing the solution for an automated assessment of availability and production losses in a PV portfolio in Australia proved very successful in improving operational efficiency and informed decision making. Process automation, data integration and automated calculations provided essential tools for effective management and improved communications with the operator. This solution sets a valuable example for the management of similar projects in the Australian solar energy sector.